Whether pre-sprouting or growing to maturity, Rota-Tech Rotary Drum turns the art of growing sprouts into a science. Rota-Tech Rotary Drum washes, sanitizes, rinses, soaks, pre-sprouts and grows your seed into sprouts in one easy step. The Rota-Tech Rotary Drum System is used for commercial sprout production of sprouted seeds such as alfalfa, arugula, broccoli, buckwheat, cabbage, cauliflower, celery, clover, dill, fennel, fenugreek, garlic, leek, mustard, onion and radish. The RT-1000 Rotary Drum is loaded with features including clear quadrants that enhance photosynthesis for healthier looking sprouts and easier hulling. The clear quads require fewer lights and less electricity, enabling visual monitoring from any angle. All Rota-Tech Rotary Drums have a stainless steel frame and are shipped fully assembled for easy installation, requiring only a water source and an electrical outlet. Get in touch with us for a complete list of Rota-Tech Rotary Drum System specifications. Contact Us

Whether pre-sprouting or growing to maturity, Rota-Tech Rotary Drum turns the art of growing sprouts into a science. Rota-Tech Rotary Drum washes, sanitizes, rinses, soaks, pre-sprouts and grows your seed into sprouts in one easy step. The Rota-Tech Rotary Drum System is used for commercial sprout production of sprouted seeds such as alfalfa, arugula, broccoli, buckwheat, cabbage, cauliflower, celery, clover, dill, fennel, fenugreek, garlic, leek, mustard, onion and radish. The RT-1000 Rotary Drum is loaded with features including clear quadrants that enhance photosynthesis for healthier looking sprouts and easier hulling. The clear quads require fewer lights and less electricity, enabling visual monitoring from any angle. All Rota-Tech Rotary Drums have a stainless steel frame and are shipped fully assembled for easy installation, requiring only a water source and an electrical outlet. Get in touch with us for a complete list of Rota-Tech Rotary Drum System specifications. Contact Us

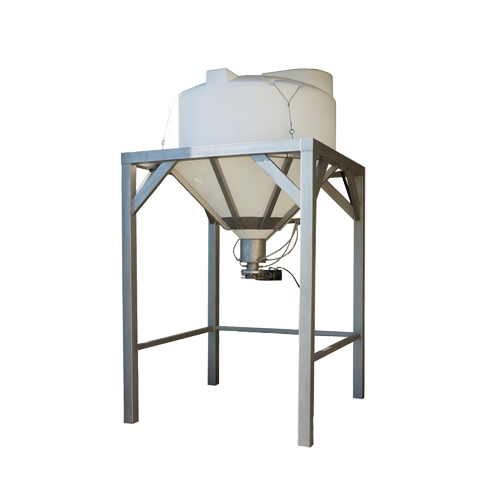

The small wash tank is the perfect addition to your sprouting facility. The small wash tank effectively cleans and hulls your sprouts all in one short step. Using a combination of air and water this piece of equipment will be sure to add value to your operation.

The small wash tank is the perfect addition to your sprouting facility. The small wash tank effectively cleans and hulls your sprouts all in one short step. Using a combination of air and water this piece of equipment will be sure to add value to your operation.- Water Capacity: 150 gallons of water

- Electrical Requirements: 230 volts single phase

- Independent air supply

The New ISS Cyclone II Centrifuge is fast, strong and easy to operate. In just thirty seconds, the Cyclone II can extend the crispness and freshness of 50 pounds of product by as much as 30%. Standard Features

The New ISS Cyclone II Centrifuge is fast, strong and easy to operate. In just thirty seconds, the Cyclone II can extend the crispness and freshness of 50 pounds of product by as much as 30%. Standard Features- Precision engineered frame to handle unbalanced loads

- Slider bar allows quick in and out of centrifuge baskets

- Designed for easy interior and external cleaning

- All food grade materials

- Variable time and speed controls for multiple products

- Superior quality continuous welded stainless steel frame with baked on finish protection to resist chlorine

- Energy efficient wash down electrical components

- Automatic and manual shutoffs

- Emergency shutoff control

- Designed so a fork lift or pallet jack can easily move it

- 20 years of experience in centrifuge design and manufacturing

- Engineering support available to best suit your product

Standard Features

Standard Features- 304 stainless steel frame

- Available tank in 304 stainless steel or polyethylene plastic

- Water tempering

- Automatic addition of chemicals

- Versatile programmable controls

- Automatic skimmer to remove debris

- Easy access bottom release of seed

- Stairs or conveyor belt to load seed into hopper.

- Automatic release of specified amounts of soaked seed, for even distribution into growing containers.

- CIP cleaning system

- Available in custom sizes. Stands can be built to your specified height.

Designed for use with your conveyor or ISS Shaker Table, the ISS Air Knife system is a high velocity air jet that blows water off your sprouts prior to packaging. It follows the washing or hydro cooling stage at harvest, prior to packaging. A wide variety of sizes and air capacities are available to suit your exact needs. ISS manufactures sprout air knife systems in a variety of sizes, but the features and specifications of our most popular size include:

Designed for use with your conveyor or ISS Shaker Table, the ISS Air Knife system is a high velocity air jet that blows water off your sprouts prior to packaging. It follows the washing or hydro cooling stage at harvest, prior to packaging. A wide variety of sizes and air capacities are available to suit your exact needs. ISS manufactures sprout air knife systems in a variety of sizes, but the features and specifications of our most popular size include:- 5 Fully adjustable air knives.

- 1 10 hp, high volume blower .

- 1 Discharge nozzle/air splitter.

- 5 Flexible duct sections.

- 1 Adapter - 8”.

- 5 Duct clamps - 4”.

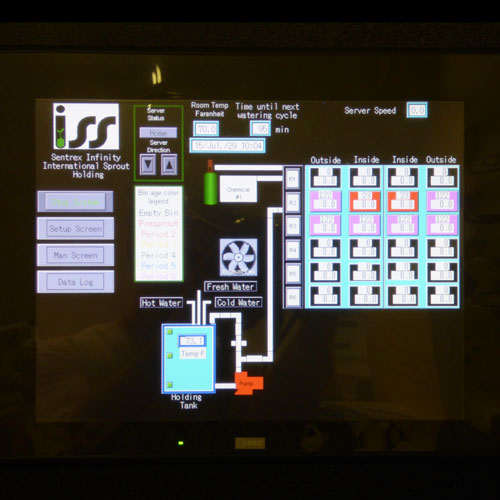

Bean sprout production is a water-intensive enterprise. In addition to needing water for growth, sprouts require frequent rinsing to regulate mass temperature and to clear away harmful byproducts. On average, it takes 11.4 gallons of water to grow 1 lb. of top quality bean sprouts. A typical Sentrex Infinity Bean Sprout Growing Room producing 60,000 lbs. of sprouts requires 662,400 gallons of water from pre-sprout to harvest for a total water cost of approximately $3,974. But with ISS water recycling equipment, the cost of water per growing room can be reduced to $397 or less. As a leader in sprout hydroponics, ISS has perfected a system capable of recycling large amounts of irrigation water. The ISS Encore Water Reclamation System recovers water, while your growing crops raise the temperature of the circulated water, reducing the amount of energy required to heat the incoming water. Consequently, Encore not only drastically reduces your water and sewer bill, but also reduces the amount of energy necessary for heating your incoming water supply. Contact Us

Bean sprout production is a water-intensive enterprise. In addition to needing water for growth, sprouts require frequent rinsing to regulate mass temperature and to clear away harmful byproducts. On average, it takes 11.4 gallons of water to grow 1 lb. of top quality bean sprouts. A typical Sentrex Infinity Bean Sprout Growing Room producing 60,000 lbs. of sprouts requires 662,400 gallons of water from pre-sprout to harvest for a total water cost of approximately $3,974. But with ISS water recycling equipment, the cost of water per growing room can be reduced to $397 or less. As a leader in sprout hydroponics, ISS has perfected a system capable of recycling large amounts of irrigation water. The ISS Encore Water Reclamation System recovers water, while your growing crops raise the temperature of the circulated water, reducing the amount of energy required to heat the incoming water. Consequently, Encore not only drastically reduces your water and sewer bill, but also reduces the amount of energy necessary for heating your incoming water supply. Contact Us

Pack Off Tables

ISS Pack Off Tables speed up the process of packaging sprouts in 4 – 20 lb. (2 – 10 kg.) plastic bags. Featuring either one or two shoots, Pack Off Tables receive sprouts from a wash tank, shaker table, air knife or centrifuge, dramatically reducing your operation’s manual packaging requirements. All ISS Pack Off Tables are made of stainless steel. At the bottom of each shoot, there is a scale as well as a solenoid to hold the plastic bag firmly in place. The scales are designed to notify the operator once the desired volume of sprouts have been fed into the bag, based on custom packing specifications. On average, the use of an ISS Pack Off Table shaves at least 50% off the amount of time it would take to pack sprouts by hand.Contact Us

The Sentrex Sprout Equipment Division of ISS manufactures a full range of affordable equipment for commercial sprout growers around the world. Backed by more than 34 years of research and commercial sprout production, ISS has a reputation for designing and manufacturing the finest sprouting equipment in the industry. Field-tested in our own sprout company, Sungarden Sprouts, The Sentrex Sprout Equipment is designed to produce exceptionally high quality sprouts while reducing operating costs, risk of injury and total overhead. Our equipment also incorporates features that streamline cleaning and sanitation so you can inexpensively maintain your equipment for years to come. We build bean sprout and green sprout equipment of all sizes, giving you access to the equipment you need to meet the unique requirements of your sprout growing operation. Contact Us

The Sentrex Sprout Equipment Division of ISS manufactures a full range of affordable equipment for commercial sprout growers around the world. Backed by more than 34 years of research and commercial sprout production, ISS has a reputation for designing and manufacturing the finest sprouting equipment in the industry. Field-tested in our own sprout company, Sungarden Sprouts, The Sentrex Sprout Equipment is designed to produce exceptionally high quality sprouts while reducing operating costs, risk of injury and total overhead. Our equipment also incorporates features that streamline cleaning and sanitation so you can inexpensively maintain your equipment for years to come. We build bean sprout and green sprout equipment of all sizes, giving you access to the equipment you need to meet the unique requirements of your sprout growing operation. Contact Us

The TRAC System is a compact, well-organized system that that minimizes time and labor requirements, creating a cleaner and more streamlined green sprout growing process. In a 10 x 21 ft. (3m x 6.4m) area, the standard TRAC I system will produce over 3,000 lbs. (1360.8 kg) of finished bulk sprouts per harvest, or nearly 700 12-pack cases of container grown sprouts. Used in conjunction with our Rota-Tech drum sprouting system, our TRAC III system can achieve up to 18,000 lbs. (8,181 kg) per week. The TRAC System is available in three, expandable models: TRAC I, TRAC II and TRAC III (capable of growing 6,000 lbs. (2721.56kg) per harvest or 18,000 lbs. (8,182 kg) per week when used in conjunction with our Rota-Tech System. TRAC System features and benefits include:

The TRAC System is a compact, well-organized system that that minimizes time and labor requirements, creating a cleaner and more streamlined green sprout growing process. In a 10 x 21 ft. (3m x 6.4m) area, the standard TRAC I system will produce over 3,000 lbs. (1360.8 kg) of finished bulk sprouts per harvest, or nearly 700 12-pack cases of container grown sprouts. Used in conjunction with our Rota-Tech drum sprouting system, our TRAC III system can achieve up to 18,000 lbs. (8,181 kg) per week. The TRAC System is available in three, expandable models: TRAC I, TRAC II and TRAC III (capable of growing 6,000 lbs. (2721.56kg) per harvest or 18,000 lbs. (8,182 kg) per week when used in conjunction with our Rota-Tech System. TRAC System features and benefits include:- Clean, sanitary sprouting system that reduces disease

- Simplifies the growing process

- Saves time and labor, resulting in cost savings

- Provides a consistent output every time

- Expands easily as your company grows

- Grows a variety of products: Alfalfa, Broccoli, Barley, Buckwheat, Cabbage, Clover, Cress, Mustard, Onion, Pea, Radish, Sunflower, Wheatgrass, and others.

- Available with PC control for multiple systems

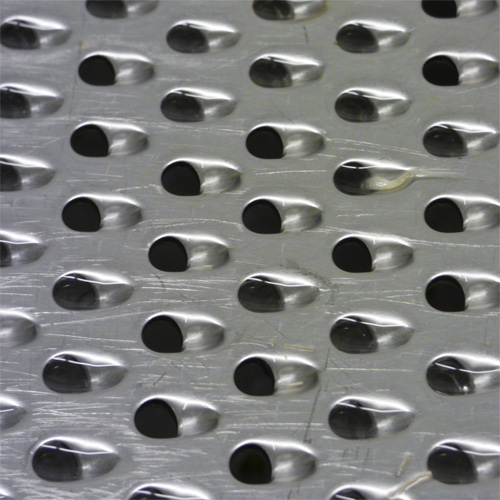

ISS Vibrating Hullers (or “shaker tables”) are capable of efficiently hulling, rinsing and conveying mung bean sprouts in a single operation. Manufactured in a variety of sizes and configurations, our Vibrating Huller saves time over batch-type washing machines, loosening the hulls (coats) while powerful water jets disperse them through perforated stainless steel decking. Sturdy construction promises the best possible bean sprout hulling and years of trouble-free service. Features include:

ISS Vibrating Hullers (or “shaker tables”) are capable of efficiently hulling, rinsing and conveying mung bean sprouts in a single operation. Manufactured in a variety of sizes and configurations, our Vibrating Huller saves time over batch-type washing machines, loosening the hulls (coats) while powerful water jets disperse them through perforated stainless steel decking. Sturdy construction promises the best possible bean sprout hulling and years of trouble-free service. Features include:- Welded stainless steel frame, (screen & machine)

- Removable stainless steel perforated screen deck for cleaning

- Single or three phase motor

- Stainless steel spray pipes (optional)

- Dimensioned to your specifications

- One ISS Eccentric Drive Vibratory Conveyor 6 feet long

- 3-foot pan, full length, x 5 inches deep, constructed of T-304 stainless steel.

- Bottom of pan perforated with round holes on staggered centers.

- In-feed end solid section before perforations.

- Reaction base and support frame stainless steel construction.

- Discharge chute.

- ISO drive for quite operation and long life.

- Dust proof, oil tight housing with v-belt drive.

- 230/60/1 and 230/380/460/3/60 motor suitable for wash-down. Both also offered in 50 hertz. Customer to specify voltage and provide external control.

The ISS Bean Sprout Wash System is a highly refined piece of equipment that improves sprout sanitation and safety while minimizing cleanup and maintenance requirements. The ISS wash system carries sprouts through a stainless steel tank and into “cleaning fingers”, where they are cleaned, hulled and de-rooted. Sprouts are then conveyed to your air knife, centrifuge bucket, packing table or packaging machine. The ISS control panel is capable of operating in either manual or automatic mode. The automatic mode provides maximum separation without physical damage to the final product. In manual mode, the controls allow you to increase the pace to meet tight production schedules. The control panel (which can be conveniently placed beside a key worker on the production line) controls all electrical components, including rinse water on the exit conveyor. The system is intentionally designed for easy cleaning and sanitation. With plenty of room underneath, the clear acrylic conveyor covers and gear covers are easily removable for cleaning. The entire system, including the control panel and motors, is wash-down. Additionally, no belts, motors, gears or electrical parts are exposed to the product. A three-inch (7.6cm) drain with ball valve allows quick drainage without clogging and the adjustable entrance spray bar is equipped with an easily removable end plug for cleaning. In the unlikely event that a worker falls into or gets caught in the system, all mechanical parts have idler arms that automatically adjust belts and allow for slippage under extreme pressure. The amount of pressure is adjustable by the operator. There is an emergency cord around three sides that can be reached from all four sides. When the cord is pulled, all systems shut down. The gears and motors are protected with safety shields that are unobtrusive and allow the tank to be accessed from either side. No motors or electrical parts are located over the tank or the water. ISS manufactures wash systems in a variety of sizes, but the features and specifications of our most popular size include:Contact Us

The ISS Bean Sprout Wash System is a highly refined piece of equipment that improves sprout sanitation and safety while minimizing cleanup and maintenance requirements. The ISS wash system carries sprouts through a stainless steel tank and into “cleaning fingers”, where they are cleaned, hulled and de-rooted. Sprouts are then conveyed to your air knife, centrifuge bucket, packing table or packaging machine. The ISS control panel is capable of operating in either manual or automatic mode. The automatic mode provides maximum separation without physical damage to the final product. In manual mode, the controls allow you to increase the pace to meet tight production schedules. The control panel (which can be conveniently placed beside a key worker on the production line) controls all electrical components, including rinse water on the exit conveyor. The system is intentionally designed for easy cleaning and sanitation. With plenty of room underneath, the clear acrylic conveyor covers and gear covers are easily removable for cleaning. The entire system, including the control panel and motors, is wash-down. Additionally, no belts, motors, gears or electrical parts are exposed to the product. A three-inch (7.6cm) drain with ball valve allows quick drainage without clogging and the adjustable entrance spray bar is equipped with an easily removable end plug for cleaning. In the unlikely event that a worker falls into or gets caught in the system, all mechanical parts have idler arms that automatically adjust belts and allow for slippage under extreme pressure. The amount of pressure is adjustable by the operator. There is an emergency cord around three sides that can be reached from all four sides. When the cord is pulled, all systems shut down. The gears and motors are protected with safety shields that are unobtrusive and allow the tank to be accessed from either side. No motors or electrical parts are located over the tank or the water. ISS manufactures wash systems in a variety of sizes, but the features and specifications of our most popular size include:Contact Us- Capacity: 24 tons / day

- Dimensions: 6 ft. (182.8 cm) high x 15 ft. (457.2 cm) long x 2 ft. 11 1/2 in. (90.2 cm) wide

- Tank Capacity: 750 gallons (2.840 liters)

- Shipping Weight: 2,100 lbs. (954.5 kg) (crated)

The ISS Titan Bin Rotating System allows growers to safely unload and process bins (Sentrex Systems or Infinity type) in minutes. Powered by a heavy-duty rotary actuator, our Bin Rotating unit starts and stops without hesitation. Unit features include:

The ISS Titan Bin Rotating System allows growers to safely unload and process bins (Sentrex Systems or Infinity type) in minutes. Powered by a heavy-duty rotary actuator, our Bin Rotating unit starts and stops without hesitation. Unit features include:- 3000 lb. capacity

- Stainless Steel construction

- Continuous welding

- Load-in height - 1 inch

- 3 HP Motor

- 5 GPM hydraulic Power unit with all required valves

- Primary Voltage 230/460V 50 or 60 Hz 3 phase

- Hold down push button operation